Friedman New Roof Project

|

Before: Yes, you're ready for a new roof! Existing shingles are 20 year "builder's shingles," 3-tab, one layer, with 1/2" plywood underlayment. Roof pitch is between 5/12 and 6/12 ... this is considered walkable. We will be suggesting changing over to Certainteed Landmark Lifetime Architectural Shingles -or even- Certainteed XT25 Shingles (25 year three tab, like the design you have now). |

|

|

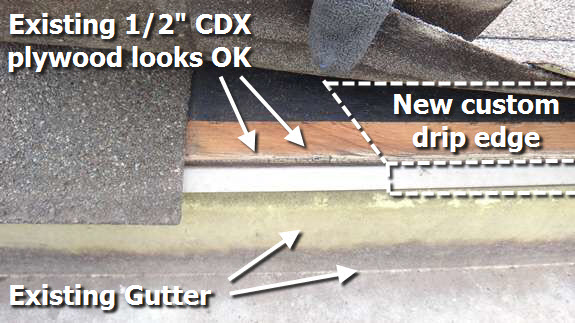

One layer of existing shingles ... 1/2" CDX plywood ... 15# roofing felt (tarpaper). As you can see, the uncovered edge of the plywood shows a little weathering; our custom drip edge will cover and protect this for good. |

Missing and worn out shingles ... |

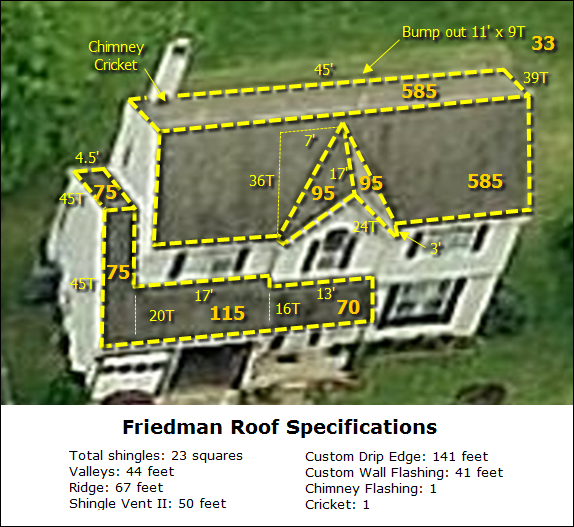

Install new pipe collars in place of existing, and ... Since we are already tearing the entire roof and felt off, it's the perfect time to cut bigger slots in the sub-roofing and install a new Shingle Vent II ridge vent system. The added volume of air circulated throughout the attic will keep the area cooler AND drier: a. Keeping the insulation dry and

making it more effective. There will be 50 linear feet of Shingle Vent II installed on this

project. |

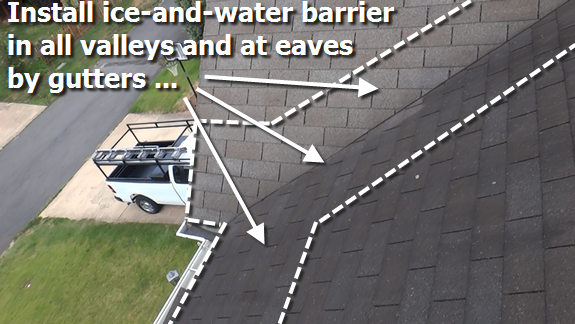

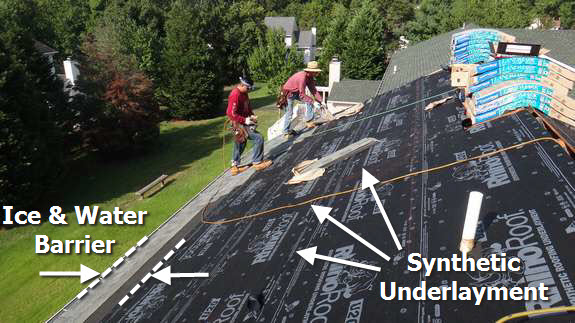

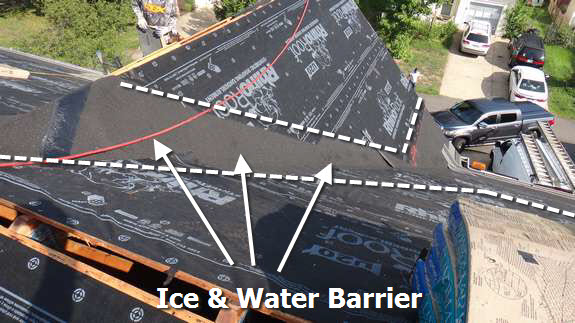

Ice and Water Shield will be added at all gutter edges, valleys, and penetrations (chimneys, etc.) to guard against ice dams and bring the existing roof "up to code." Ice and water shield permanently bonds itself to the plywood surface AND the aluminum drip edge to prevent damage to the wood sub-roof from ice dams and horizontal rain. There will be about 185 feet of material, 3 feet wide, when this job is completed. Underneath the Ice and Water Shield at the eave edges will be our Custom formed aluminum drip edges that help direct water into the gutters so that the sub-roof and fascia wood is protected from water and ice dams for the life of your roof. We custom form them on site on our sheet metal brake so that they fit your roof exactly. There will be about 141 feet of 6" wide drip edge applied to this project. Before the roofing shingles are installed,

instead of using the old fashioned "tarpaper" (that almost everybody else STILL uses), we

use Berger UDL Synthetic

Underlayment, which is

much more effective at protecting against leaks caused by "wind driven rain" ... and has the

added benefit of discouraging mold growth -- unlike tarpaper. |

We won't forget the lower "bump out" roof in the rear ... |

|

|

Wall flashings will be replaced with new (color: black) custom formed aluminum flashings; there will be 41 feet of new wall flashings installed on this project. |

|

Gutters and downspouts are in good shape and just need minor tightening of the gutter spikes, which we will do at no charge, of course ... |

If it turns out that additional "inside hangers" are needed for stability, we will install these at no additional charge as well ... |

|

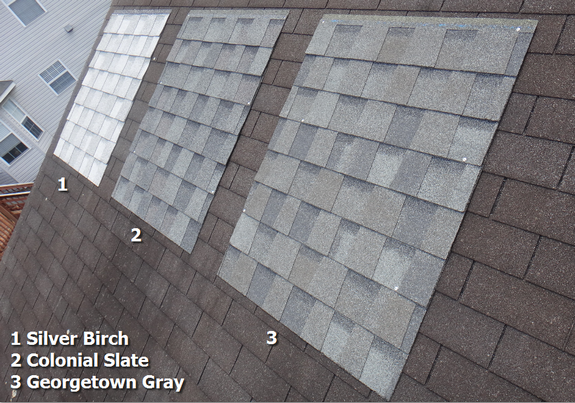

Choosing Shingle Colors:  It is very important to us that all of our customers get the exact roofing color that they love! Here's how we help: http://goo.gl/QmpqeV |

|

|

During & After Pics:  Our supplier (The Roof Center) has neatly loaded the shingles and accessories on the roof! |

...and now, the REAL work begins. Approximately 6,000 lbs. of old shingles (24 squares @ 250 lbs/sq.) will be stripped off and neatly dropped into the dump truck. |

|

|

|

|

The roof has been stripped, "de-nailed," and the ice & water barrier plus synthetic underlayment is now properly attached. |

The shingle nailing process has begun ... chalk lines are "snapped" and as you will see, helps the technicians install a "perfectly straight" roof! |

We usually find that the builder hasn't cut the plywood ridge vent slot wide enough; but in this case, it was done properly. That almost never happens! |

Ice & water barrier in all valleys and at all eaves. |

|

|

|

|

|

This is what a professionally cut "California Valley" should look like ... |

|

|

The Shingle Vent II ridge vent system is a great addition and will help move more air out of the attic. Cooler in summer, warmer in winter, and helps prevent condensation as well (and mold too!). |

Nice 'n straight! |

|

Rake edges are perfectly straight as well ... |

|

|

|

|

|

|

|

Flashings:  New neoprene/aluminum pipe collars installed, pipes painted to match with high quality oil based Rustoleum Paint. |

|

|

|

|

|

Gutters tightened up very nicely, and new drip edge now protects plywood and fascia. |

Final Product, New Certainteed Landmark Lifetime Roof:  |

|

Done deal! |

|

|

|

|

%20837-7400.png)